Tech Tactics That Are Shortening the Build Timeline

Building timelines has become the make-or-break factor for companies trying to stay competitive in today’s fast-paced market. What used to take months or even years can now be accomplished in weeks, thanks to innovative technology solutions that are revolutionizing how we approach project execution.

The pressure to deliver faster while maintaining quality has never been higher, and traditional methods simply can’t keep up with modern demands. Investing in execution management is worth it—organizations that successfully enhance their execution capacity increase their profitability by 77%. This dramatic improvement shows just how powerful the right tech tactics can be when properly implemented.

Revolutionary Manufacturing Technologies Changing the Game

The manufacturing landscape has undergone a complete transformation, with cutting-edge technologies leading the charge in reducing build timelines. These innovations aren’t just incremental improvements—they’re game-changers that fundamentally alter how products move from concept to completion.

Advanced Printing Solutions

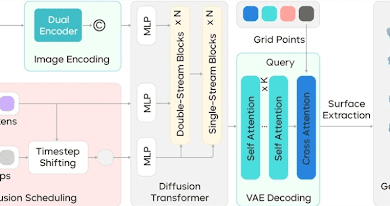

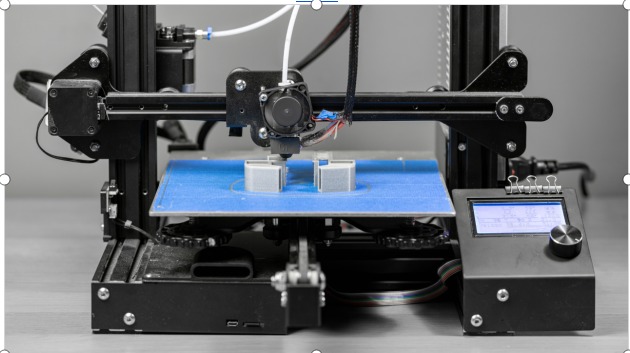

One of the most significant breakthroughs in rapid prototyping and production has been mjf 3d printing, which offers unmatched speed, precision, and scalability. This technology allows manufacturers to create complex parts in hours rather than days, eliminating traditional tooling requirements that often create bottlenecks.

The precision and speed of multi jet fusion technology have made it possible to produce functional prototypes and end-use parts simultaneously, cutting development cycles dramatically.

Mjf printing offers unique advantages over conventional manufacturing methods, particularly in its ability to handle multiple materials and complex geometries without additional setup time. Companies using this technology report timeline reductions of 60-80% compared to traditional manufacturing approaches.

Automated Assembly Systems

Modern automated systems have transformed assembly processes by reducing human error and increasing consistency. These systems can work continuously without breaks, significantly accelerating production schedules while maintaining quality standards.

Smart assembly lines equipped with sensors and AI-driven controls can adapt to different product configurations on the fly, eliminating downtime typically associated with changeovers. This flexibility has become crucial for companies dealing with diverse product lines and varying order quantities.

Digital Integration Tools

Digital twins and simulation software allow engineers to test and refine designs before physical production begins. This upfront investment in digital modeling prevents costly mistakes and reduces the need for multiple physical prototypes, streamlining the entire development process.

Cloud-based collaboration platforms enable teams across different locations to work simultaneously on projects, eliminating the delays caused by sequential handoffs between departments. These tools have become essential for maintaining momentum in complex projects.

Software Solutions Accelerating Project Delivery

Project management software has evolved far beyond simple task tracking to become sophisticated platforms that can predict potential delays and suggest corrective actions. These solutions are transforming how teams coordinate and execute their work.

Project Management Platforms

Modern project management platforms integrate seamlessly with manufacturing systems, providing real-time visibility into production schedules and resource allocation. They can automatically adjust timelines based on actual progress and identify potential bottlenecks before they impact delivery dates.

Hp 3d printer integration with project management systems allows for automatic scheduling of print jobs based on project priorities and deadlines. This coordination ensures that critical components are produced first, optimizing overall project flow.

Real-Time Monitoring Systems

IoT sensors and monitoring systems provide continuous feedback on production progress, equipment performance, and quality metrics. This constant stream of data enables proactive decision-making rather than reactive problem-solving.

Dashboard systems aggregate information from multiple sources, giving project managers a comprehensive view of project status at any given moment. This transparency helps identify issues early and allows for rapid course corrections.

Predictive Analytics Tools

Machine learning algorithms can analyze historical project data to predict potential delays and suggest preventive measures. These tools become more accurate over time, learning from each project to improve future predictions.

Mjf printer utilization data combined with predictive analytics can optimize print scheduling and material ordering, ensuring that production capacity is maximized while minimizing waste and delays.

Automation Tools Streamlining Workflows

Automation has moved beyond simple repetitive tasks to encompass complex decision-making processes that traditionally required human intervention. These tools are eliminating bottlenecks and accelerating project completion.

Robotic Process Automation

RPA systems can handle routine administrative tasks like order processing, documentation, and status updates automatically. This frees up human resources for more strategic activities while ensuring that routine tasks don’t slow down project progress.

Automated approval workflows can route documents and decisions through the proper channels without manual intervention, significantly reducing approval times that often create project delays.

Quality Control Systems

Automated quality control systems can inspect products in real-time during production, identifying defects immediately rather than waiting for end-of-line testing. This early detection prevents rework and reduces the time needed for quality assurance.

Vision systems and AI-powered inspection tools can evaluate complex geometries and surface finishes with greater accuracy and speed than manual inspection methods.

Resource Optimization

Smart scheduling systems can automatically allocate resources based on project priorities, skill requirements, and availability. This optimization ensures that the right people are working on the right tasks at the right time.

Inventory management systems can automatically reorder materials and components based on production schedules, preventing delays caused by material shortages.

Implementation Strategies for Success

Successfully implementing these tech tactics requires careful planning and execution. Companies that approach implementation systematically see the greatest benefits in timeline reduction.

Planning and Preparation

Successful implementation begins with a thorough assessment of current processes and identification of the biggest bottlenecks. This analysis helps prioritize which technologies will have the most significant impact on build timelines.

Change management strategies must be developed to help teams adapt to new tools and processes. Resistance to change can significantly slow implementation if not properly addressed.

Team Training and Adoption

Comprehensive training programs ensure that teams can fully utilize new technologies from day one. Ongoing support and refresher training help maintain proficiency as systems evolve.

Creating champions within each department can accelerate adoption by providing peer-to-peer support and demonstrating the benefits of new technologies through real-world examples.

Your Questions About Build Timeline Optimization

How quickly can companies see results from implementing these technologies?

Results vary by technology type, but most companies see measurable improvements within 3-6 months of implementation. More complex systems may take 6-12 months to show full benefits.

What’s the biggest challenge in adopting these tech tactics?

Change management and team adoption represent the biggest hurdles. Technical implementation is often easier than getting teams to embrace new workflows and processes effectively.

Which technology offers the fastest return on investment?

Project management software typically provides the quickest ROI, often within 3-6 months, because it improves coordination across all existing processes without requiring major equipment changes.

Wrapping Up the Timeline Revolution

The technologies discussed here aren’t just theoretical concepts – they’re practical tools that companies are using right now to dramatically reduce their build timelines. From multi jet fusion printing to sophisticated project management platforms, these innovations are reshaping what’s possible in terms of speed and efficiency.

The key to success lies not in adopting every available technology, but in carefully selecting the tools that address your specific bottlenecks and implementing them systematically. Companies that take a strategic approach to technology adoption consistently outperform those that try to implement everything at once.

Perhaps the most exciting aspect of this technological revolution is that we’re still in the early stages – the tools and techniques available today will seem primitive compared to what’s coming in the next few years.